Press

20 years of cold runner system expertise

GÜNTHER presents its entire cold runner portfolio at the K 2019 in Düsseldorf

The world production of silicones is steadily increasing. In 1974, about 130,000 tonnes was produced; in 2016, this neared 770,000 tonnes, and global sales in 2017 reached over 16.3 billion US dollars. According to market research institute Ceresanas, the silicone market will grow on average by 3.9 percent until 2025. This indicates that silicone and LSR processing is no longer a niche market. Today, silicone is processed in almost every industry – the automotive, electrical/electronics or medical technology industries. One field of application where its importance is growing is the food industry. The material has the advantage that it is virtually re-work free and can be processed fully automatically. GÜNTHER, known as a technology leader in the field of hot runner technology, also has 20 years of expertise in cold runner technology. At the K – the world’s largest plastics trade fair – GÜNTHER is highlighting its portfolio of innovative technology for silicone and LSR processing.

Injection molding of two-component liquid silicone first began in the early 1980s. Products made from Liquid Silicone Rubber (LSR) are versatile due to its universal material properties. In the automotive industry, for example, this ranges from switch covers and protective caps to membranes for central locking systems and headlight seals. Electrical engineering uses the material for safety mats, anode caps and electrical plugs or as protective material for printed circuit boards. LSR components are also used in medical technology, for example as cardiac catheters, teats and pacifiers for babies, contact lenses or respiratory masks. Sealing rings, jet inserts or seals for mixer taps are examples of applications in household and sanitary technology. The food industry values the physiological safety of certain approved types as well as the sterilizing capability by means of heat or gamma rays, but also the tasteless and odorless properties of the material. And thanks to the development of material properties, new fields of application are emerging, says Hans-Peter Resler, Technical Advisor LIM at Enbi Plastics BV in Holland, who has been active in the market since the very beginning. Enbi Plastics sees itself as a knowledge mediator and co-creator in the field of plastic and silicone products. From engineering, prototyping, test forms, production as well as assembly and packaging, the Dutch company offers everything from a single source. “Especially its material properties, such as continuous temperature resistance in the range of -50 C to 230 C or virtually unchanged rubber-mechanical properties over the entire temperature range, make this material so interesting. Its almost constant electrical properties, excellent aging and weather resistance and ozone and UV stability are also worth mentioning, as well as the additional material adjustment options such as oil bleeding (self-lubricating), reduced flammability, increased transparency or increased Shore A hardness.” Processing began in 1978 as Franz Sterner Werkzeugbau constructed the first injection molding tool for liquid silicone rubber. Sterner is considered a pioneer in silicone processing.

At that time, the LSR market was still in its infancy, remembers Resler. Processing liquid silicone and tooling is extremely demanding, but mold-making is in a class of its own. LSR is mixed from two components, and this mixture has an extremely low viscosity level when uncrosslinked during injection into the hot mold. “LSR flows like water,” says Resler. The tools must therefore be very accurate and built absolutely tight to avoid burrs. “We first had to develop this know-how,” says Resler. “The most difficult aspect was actually the direct gate point. We sawed small needles from stainless steel pins and drilled a corresponding hole on a sub-manifold, which we drilled out piece by piece. By doing so, we were able to produce a small offset, over which the necessary shear took place. This allowed us to inject directly onto the product wall. That was the beginning. We then began to very slowly develop the concept of tool technology with injection technology.” As a result, a market for tool and mold makers developed, offering complete tools for LSR processing, which were usually coupled with a production order. “Single cold runners could not be purchased at that time,” says Resler. Resler encountered GÜNTHER Hot Runner Technology at the Fakuma trade fair. The company presented a compelling idea for developing cold runner technology. What impressed Resler was that GÜNTHER only focused on the development of hot and cold runner technology as their core business without the addition of product production unlike so many others. “That was very important to me. The second thing that impressed me was that GÜNTHER strives to find the best solution together with its customers in everything they do, what they develop, and what ideas they pursue. A real cooperation emerges,” said Resler impressed. This is how a cooperation began that is still thriving today.

When asked what characterizes a collaboration with GÜNTHER, Resler replies, “It’s based on reciprocation. GÜNTHER has a great deal of knowledge and experience in hot and cold runner technology, how to control temperatures and shear and thus vulcanization. At Enbi Plastics, we have hands-on experience with processing LSR and what problems can arise. It is always about listening, thinking and combining. The simple construction, modular nozzle design and excellent thermal separation between the nozzle and cavity are the decisive advantages of GÜNTHER hot runner technology for developing excellent cold runner system solutions,” summarizes Resler. Therefore, GÜNTHER can also offer both the cold half and hot-cold half as standard parts.

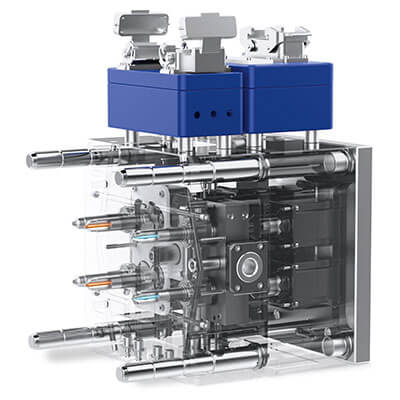

GÜNTHER configures cold runner solutions for LSR processing in Frankenberg with the same level of passion as in its designs for hot runner systems. GÜNTHER cold runner systems ensure high availability, significant material savings, the best possible cycle times and consistent, excellent quality of the molded parts produced. Cold runner nozzles from GÜNTHER exhibit good thermal separation to the hot cavity plate. This reduces heat transfer and prevents premature crosslinking. Moveable fixation of the needle guide or the nozzle part also contribute to excellent compensation of thermal expansion. All nozzle heads are equipped with an insulation disc to ensure optimal thermal separation from the hot nozzle holding plate. The heated nozzle holding plate is also equipped with an insulation plate to minimize heat emission. The metallic contact between the needle guide and the heated tool is designed to stay at a minimum, in order to transport as little heat as possible to the cold runner nozzle. “This is where GÜNTHER has gathered vast experience and expertise and has implemented it in an intelligent manner,” notes Resler as an LSR expert. Furthermore, the nozzle shaft includes a sealing ring, which also protects against leaks.

The nozzles can be used either individually or in a collection housing for tighter cavity spacing. Thanks to the variable needle stroke setting, filling differences can be easily compensated. The maintenance-friendly, balanced cold runner manifold system from GÜNTHER features gentle flow in the melt channel. The system is designed so that it can be easily disassembled and opened for cleaning. It is also possible to quickly and easily replace the standardized wear parts such as the nozzle part, needle guide, needles and seals if necessary.

The GÜNTHER cold runner system portfolio includes the 5NEW80 single cold runner valve gate nozzle, the 5DEW80 single cold runner nozzle, the NTKW system cold runner nozzle, the NMW system cold runner nozzle and the SMA 10 stepper motor for complex applications with up to four different needle positions per cycle. The DPE control unit can control up to 16 stepper motors with high precision. In addition, the position of each individual shut-off needle in the mold can be set individually with the control unit. The GÜNTHER cold runner portfolio also includes the ANES sliding mechanism and the ANEH pneumatic multi-needle drive. GÜNTHER also offers a complete cold half that can be purchased as a standard part and efficiently integrated into corresponding tools.

OTHER INNOVATIONS AT THE K

At the K 2019, The World’s No. 1 Trade Fair for Plastics and Rubber, from October 16-23, 2019 in Düsseldorf, GÜNTHER Hot Runner Technology will be presenting other innovations in addition to its innovative cold runner technology. With the launch of the BlueFlow® hot runner nozzle, GÜNTHER set new standards in terms of energy saving and a particularly slim nozzle design at the K2010. Now, nine years after first presenting the “Blue Nozzle,” new innovations in the BlueFlow® product range will be presented at the trade fair.

As part of the K, GÜNTHER will also be presenting the relaunch of the CADHOC® System Designer, the configuration program for individual components and complete hot runner systems. User suggestions have been collected over the years and are now reflected in the relaunch. Not only has the usability of the configuration program been improved, but new save functions for configurations have also been introduced. This ensures that users can always access completed configurations and can use them as a template for new designs as needed. Additional features of the CADHOC® System Designer will be presented to the public at the K Trade Fair.

Visit GÜNTHER in Düsseldorf at the K in Hall 1 – Stand C44.