Press

GÜNTHER – resource-efficient hot runner systems

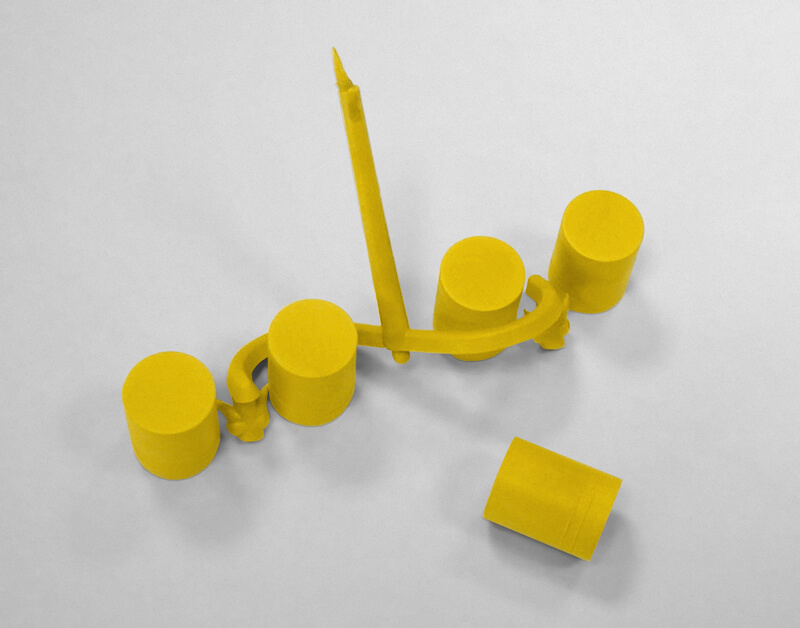

Saving materials thanks to innovative hot runner technology

Plastic is a future-oriented material that takes global megatrends into account. For instance, plastics help supply the world’s growing population with food and drinking water. As a component for clean energy, they are also used in wind turbines or solar cells and thus help to protect the climate. They optimize lightweight construction in cars and aircraft to ensure future mobility.

Plastics are also eco-efficient, provided they are recycled correctly. Development of a functioning circular economy for polymer materials is therefore a key goal for the future.

GÜNTHER Hot Runner Technology is also prioritizing resource conservation with innovative solutions. “This is because I don’t need to recycle or destroy plastic granulates that I don’t use during manufacture. Resource saving starts with the product design and tool construction themselves,” explains Horst-Werner Bremmer, Head of Technical Application Consulting and Sales at GÜNTHER.

“Many engineers design their products in such a way that direct gating is often not possible, for example, meaning complex sprue designs are required.” He takes the material savings on manufacturing an LCP front cap as an example, where the part weight was 1.11 g, the gating weight 3.15 g and the shot weight 7.59 g. After changing over to a hot runner with a valve gate, the shot weight was reduced to 4.44 g. “The planned production run was 1.5 million parts in this case. 2.8 t of granulate would have been needed if a hot runner system hadn’t been used. Conversion to a hot runner with a valve gate meant that 1.2 t of material could be saved,” calculates Bremmer. Innovative hot runner technology can thus help conserve resources significantly.

About GÜNTHER Hot Runner Technology

As a technological leader in the field of hot and cold runner technology with more than 230 employees, GÜNTHER produces innovative, user-friendly injection systems for the plastics and silicone processing industry. Its international customers include leading companies in the automotive, health technology, packaging, consumer goods, and electronic and electrical engineering industries.